Number One Plate

Number One Plate is a manufacturing innovation product for the 4th industrial revolution and digitalization.

From 0.5mm thickness of heat treated grinded standard plate.

Number One Plate Unit Price List

Number One Plate

We can provide a wide range of steel products by the world's top steel companies.

DAIDO . Hitachi(Japan) . Bodycote(Sweden) . Seah&Changwon(S.Korea) . Thyssen(Germany) . Bohler(Austria) . Uddeholm(Sweden)

Procedures for providing number one plate

Supply of accurate & suitable raw materials at customer's request

01

(Cutting raw materials)

02

(6 side milling machining)

03

(Stress removal and demagnetization)

Procedures for providing number one plate

Number one heat treatment

04

(Normal quenching)

05

(Number one sub-zero)

06

(Number one tempering)

Procedures for providing number one plate

Number one precision plane grinding

07

(Stress removal and demagnetization)

08

(Super-precision unmanned grinding)

Procedures for providing number one plate

Super-fast delivery

09

10

(Packing, Shipment)

Key Features of Number One Plate

Advantages of using Number One Plate compared to Generally used heat treatment abrasive products

Pre-discharge wire cutting using W-EDM

Generally used heat treatment abrasive products (Distortion)

Shape deformation by stress

Number One Plate

(Flatness retention)

(Flatness retention)

Little stress deformation despite fast cutting

Key Features of Number One Plate

The best conditions for processing with the highest quality grinded surface

01. Available for sale from 0.7mm in thickness

(Contact with us if you need even thinner products)

02. Distortion tolerance +0 ~ -0.1

(1x100x200)

(Contact with us if you need even thinner products)

02. Distortion tolerance +0 ~ -0.1

(1x100x200)

Removing stress and heat treating provide products with minimal grinded surface tolerance range that customers can use without further processing

Key Features of Number One Plate

Enhancement of toughness by grain directional cutting of raw material (Avoid damage)

High quality material from global steel producers

Purchasing of excllent raw materials inspected by the world’s top steel manufacturers

Increasing toughness by grain direction

Grain directional cutting, machining, heat treatment, grinding

Maximizing toughness

Minimizing the possibility of damage during use

Comparative Advantage

Comparison of cost saving, Fast delivery

| Comparison | Material | 6 side milling | Heat treatment | Grinding | Total cost | Cost save |

|---|---|---|---|---|---|---|

| Competitor A | A | B | C | D | =A+B+C+D | 100% |

| Number One Plate | Standard price | =A+B+C | 75~78% | |||

Price competitiveness

Number One Plate = The price of A+B+C

22~25% more cost saving than other companies, by excluding the cost of grinding.

Comparative Advantage

Delivery competitiveness

| Comparison | Material | 6 side milling | Heat treatment | Grinding | Delivery | Time save |

|---|---|---|---|---|---|---|

| Competitor A | 1 day | 1 day | 3 days | 1 day | =5 days | 100% |

| Number One Plate | 1 day (when in stock) | =1 day | 20% | |||

* 4 days-saving when in stock

| Comparison | Material | 6 side milling | Heat treatment | Grinding | Delivery | Time save |

|---|---|---|---|---|---|---|

| Competitor A | 1 day | 1 day | 3 days | 1 day | =5 days | 100% |

| Number One Plate | 3 days | =3 days | 60% | |||

* 2 days-saving when out of stock

How to choose a steel grade

Guidelines for choosing special steels, tungsten carbides, Ferro titanit

How to choose a steel grade

Selecting by characteristics

| Application | Recommendation | Hardness(HRC) |

|---|---|---|

| General material for cost reduction | SKD11.SKD61 | 56-58.50-52 |

| Wear resistance, Cost save | DC53 | 58-60 |

| High wear resistance for damages of small parts | HAP10.S790 | 61-65 |

| Gate, Core which has complicating design, Wear resistance | HAP40.S590 | 63-67 |

| Super-wear resistance | HAP72 | 68-70 |

| Breakable core, pin, as well as needed wear resistance | HAP5R | 58-62 |

| Gas-dissipating when molding, precise dimension(Minimize season distortion) | PD613 | 56-60 |

| Not needed wear resistance but only needed high toughness (Unbreakable) | YAG300 | 52-55 |

| Neat cutting edge without any burrs | Ferro titanit | 70-72 |

| Punch, dies for press mold which does not have design change | SF20 | HRA 92-94 |

Our Suppliers

Major Suppliers

Correspondence specification

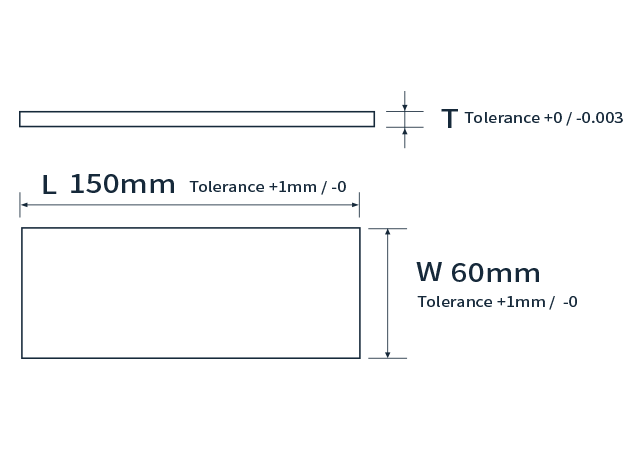

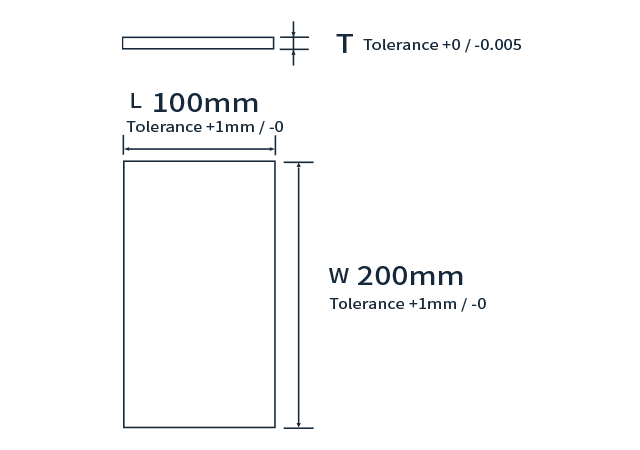

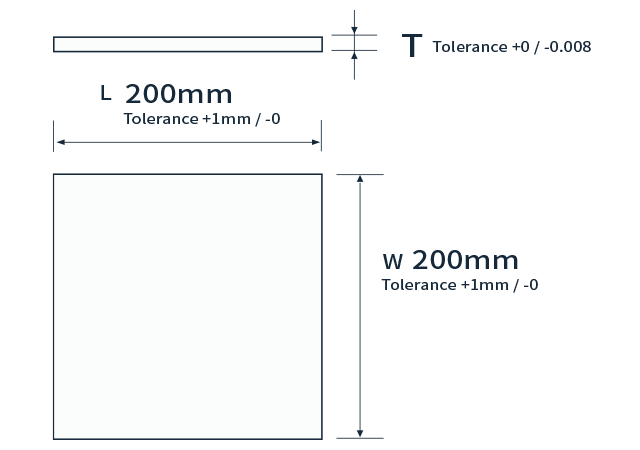

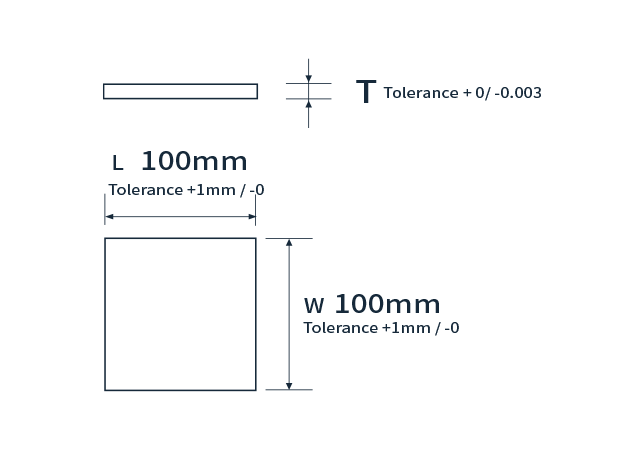

Number One Plate standard dimension & tolerance

Number One Plate Unit Price List

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Please contact us at info@ilkangtrading.com, if you need any other specification & dimension & material.

(Ex. SLD, ELMAX, RIGOR, HPM31, ASP60, SUS440C, Ferro Titanit)

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||